In modern industrial environments, equipment performance and longevity are critical factors that directly impact operational efficiency, safety, and overall cost-effectiveness. One of the most overlooked yet vital contributors to these factors is vibration management. Excessive or uncontrolled vibrations can reduce equipment lifespan, compromise precision, and lead to costly downtime. This is where cluster vibration damping solutions come into play, offering industrial operations a strategic advantage in optimizing equipment performance.

Understanding Cluster Vibration Damping

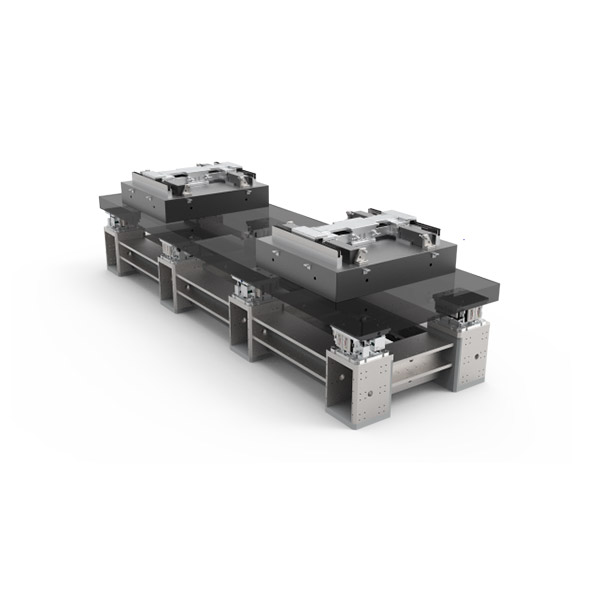

Cluster vibration damping solutions are advanced systems designed to minimize or eliminate the negative effects of mechanical vibrations in industrial equipment. Unlike conventional vibration control methods, which often focus on individual components, cluster solutions address multiple vibration sources simultaneously. By using integrated platforms, these systems ensure that all connected machines operate harmoniously, reducing stress, wear, and tear.

Benefits of Implementing Cluster Vibration Damping Solutions

-

Enhanced Equipment Precision and Stability

Industrial machinery often requires micrometer-level precision, especially in sectors such as semiconductor manufacturing, aerospace, and precision engineering. Vibrations, even those imperceptible to the human eye, can affect measurements and processes. Cluster vibration damping solutions absorb and isolate these disturbances, ensuring consistent performance. -

Extended Equipment Lifespan

Continuous exposure to vibrations accelerates mechanical fatigue, loosens fasteners, and degrades sensitive components. By controlling vibration at a cluster level, industrial equipment experiences less stress, reducing maintenance frequency and extending operational lifespan. -

Increased Operational Safety

Excessive vibration can pose significant safety risks, from machine malfunctions to structural damage. By implementing vibration damping solutions, factories can prevent hazardous conditions, ensuring a safer working environment for employees. -

Reduced Downtime and Maintenance Costs

Equipment that operates with uncontrolled vibrations is prone to breakdowns. Cluster vibration damping solutions help maintain optimal working conditions, minimizing unexpected failures and lowering the total cost of ownership.

Advanced Technology from Wuhan Glory Road Precision Technology Co., Ltd.

A leading example of innovation in this field is Wuhan Glory Road Precision Technology Co., Ltd., a manufacturer specializing in active vibration isolation equipment. Their advanced active vibration isolation platforms, precision motion controllers, and fully integrated mechatronic systems provide customers with decisive competitive advantages. By combining cutting-edge control technology with robust mechanical design, their solutions adapt to dynamic industrial environments, actively counteracting vibrations in real time.

For businesses looking to maintain peak equipment performance, Glory Road’s cluster vibration damping systems offer:

-

Real-time vibration monitoring and suppression

-

Seamless integration with existing industrial machinery

-

Customizable platforms to meet specific operational needs

Applications Across Industries

Cluster vibration damping solutions are essential in industries where precision and reliability are non-negotiable. Common applications include:

-

Semiconductor and Electronics Manufacturing: Protects sensitive production lines from external vibrations.

-

Aerospace and Automotive Testing: Ensures accurate measurements and testing results.

-

Precision Engineering: Enhances milling, grinding, and other high-precision machining processes.

-

Medical Equipment Manufacturing: Maintains stability for imaging devices and diagnostic machinery.

Conclusion

Incorporating a cluster vibration damping solution is no longer optional but a strategic necessity for industrial operators seeking to optimize performance and longevity. By mitigating vibration-related challenges, companies can improve equipment precision, reduce maintenance costs, and ensure safer operations. With innovative solutions from Wuhan Glory Road Precision Technology Co., Ltd., businesses can harness the full potential of their machinery, gaining a significant competitive edge in today’s demanding industrial landscape.

www.glroadprecision.com

Wuhan Glory Road Precision Technology Co., Ltd.